Publication:

Mobile, Wearable, and Ubiquitous Tech. Paper: ACM IMWUT ‘23 | View The Paper Here!

Robotics and Automation Paper: IEEE RA-L, IROS ‘22 | View The Paper Here!

Design of ForceSticker:

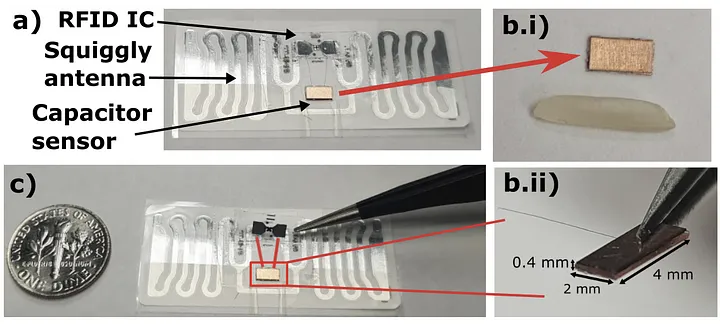

We show that the force information can be piggybacked over existing RFIDs, with no additional power and no requirement for any interfacing electronics, by simply interfacing a force-sensitive capacitor to the RFID. The designed force-stickers consist of a thin parallel-plate capacitor, smaller than a rice grain, that deforms under applied force and is interfaced between the RFID squiggly antenna and the RFID IC. But how does the force information from the capacitor get communicated via the RFID IC, without requiring any more electronics or power? The secret sauce lies in the capacitor design—choosing the correct polymer and dimensions!

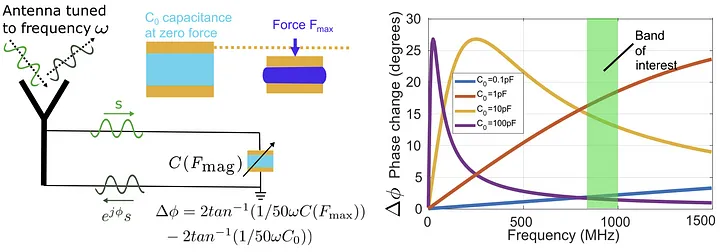

When a capacitor is interfaced to an antenna, it shows a non-linear relationship between frequency, capacitance, and phase change. We find that when the capacitor is designed in the 1–10 pF range, the phase change effect is sensitive to the RFID frequency of 900 MHz.

Shows ForceSticker components. a), b.i), b.ii) Show the capacitor sensor compared to a rice grain. Zoomed-in view c) shows how the capacitor sensor is attached to the RFID IC (peeled off in the image via tweezers) via hair-like tungsten filaments highlighted in red, visible more clearly in a) and b.ii).

Experiments with ForceStickers:

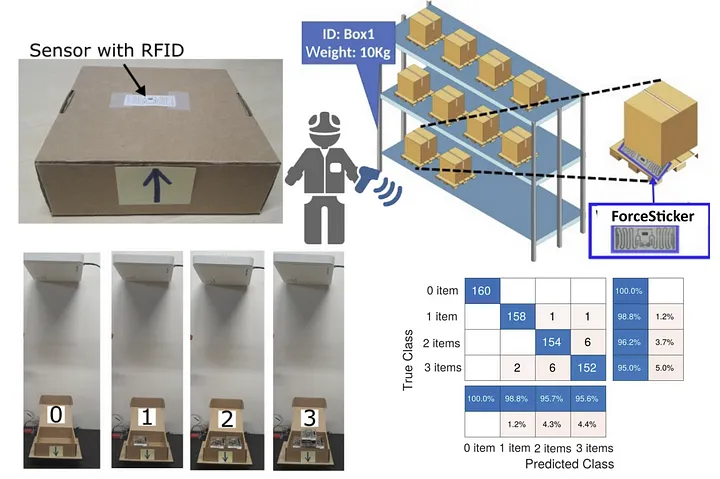

Package Consistency Checks with ForceStickers:

We show that by sticking ForceStickers to the bottom of packages, we can sense weight and determine the number of items inside, for consistency checks in warehouse settings. We took 160 measurements with different numbers of items (RPis placed in the package) and obtained a classification confusion matrix.

Sensing Knee-Impact Forces:

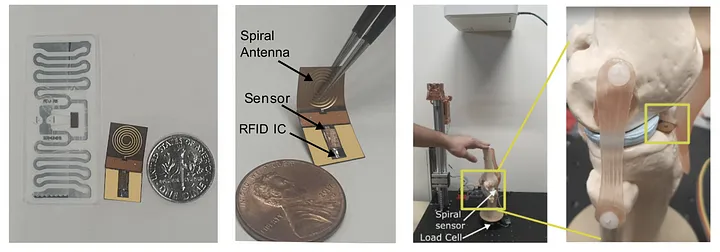

We show how ForceSticker can be prototyped with a custom flexible PCB RFID, which allows us to make a 2× smaller ForceSticker—small enough to sense forces from a knee joint.

This showed that ForceSticker can even be used in scenarios like knee implants, which are irregularly shaped and highly space-constrained. Further, by monitoring the knee joint forces over time, the implant’s fit and function can be evaluated, as well as its health—if the implant starts wearing down, the sensed force will also change.

Cyclic Testing of ForceSticker:

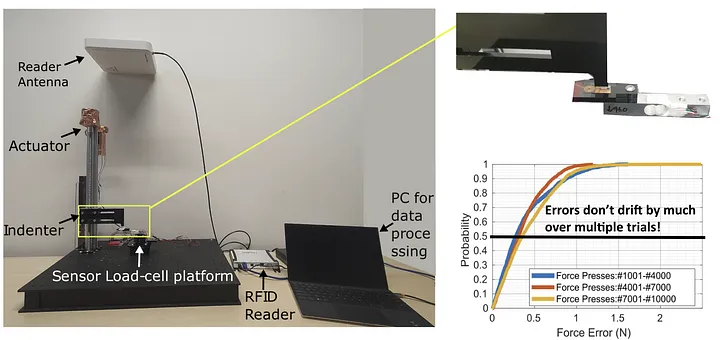

Robustness test of the sensor by applying forces on it using an in-house-developed automated actuator-based cyclic test setup.

The cyclic testing setup where an actuator applies forces on the sensor. Even after 10,000 force presses by the actuator, the sensor’s error performance remains about the same (0.3 N).

Quick Video Summary:

Future Work

Even though the sensors we designed were thin, sticker-like, and enabled the first demonstrations of a bunch of interesting applications—and even turned out to be robust—ForceSticker is still research in motion, and there is a lot of ground to cover before we can achieve the force vision shown earlier.

The biggest roadblock lies in enabling ForceStickers to work with smartphones, since the existing ForceStickers only work with dedicated RFID readers, which may not always be available. Further, we need to realize mass fabrication of these sensors (right now it is mostly manual and DIY assembly), explore commercially viable materials for everyday life applications, and develop biodegradable, hermetically sealed sensors for in-vivo use. We also need to improve the sensor’s error performance in more challenging environments, and scale performance to support large numbers of sensors.

References:

[1] “ForceSticker: Wireless, Batteryless, Thin & Flexible Force Sensors”, Gupta et al., IMWUT Issue 1 2023

[2] “WiForce: Wireless Sensing and Localization of Contact Forces on a Space Continuum”, Gupta et al., NSDI’21

[3] “Soft Radio-Frequency Identification Sensors: Wireless Long-Range Strain Sensors Using Radio-Frequency Identification”, Teng et al., SORO’19

[4] “MARS: Nano-Power Battery-free Wireless Interfaces for Touch, Swipe and Speech Input”, Arora et al., UIST’21